Hot stamping or embossing is a printing process that features heated dies or molds to transfer pre-dried inks or metal foils onto the surface. Here’s how it works:

- The embossing machine heats the engraved die or mold and presses the marking foil onto your surface.

- The foil is only deposited where the heated stamp comes into contact with the material. This lets engineers create elegant designs on assemblies and parts in post-production when they should be embossed. Machine stamping is the go-to solution for many companies.

There are typically three layers for the stamping foils: a release layer, the adherence base, and a color layer, which is either metallic or pigmented.

Using an embosser machine can be beneficial. You’ll achieve versatility, precision, and efficiency when printing on surfaces and can easily personalize and decorate products. Here are a few more benefits:

The Advantages of Emboss Machine Stamping

The biggest benefit of hot stamping with embossing machines is that you can use various product materials, such as metals, rubbers, and plastics. However, you’re not limited to them; it’s possible to stamp glass, leather, and wood. Another feature of the hot stamping foils is you may apply them to coated objects without damaging anything.

Here are a few more benefits of using an embosser machine:

Clean and Effective

Because you’re using metal foil rolls, you don’t have to clean up messy spills or mix liquid inks. It’s a more streamlined process, which means you can quickly emboss things and make them look unique.

Consistent Results

Hot stamping with an embossing machine consistently produces excellent results. It doesn’t matter what colors you use or the type (metallic or pigment); the adherence base will strongly grip the product surface to make sure you get the look you want.

Just be aware that some materials require specialty foils to adhere correctly. Leather is one good example of this. Therefore, product managers should understand that and keep it in mind.

Might Remain Forever

Marking foils are designed for durability, but environmental conditions might cause fading in time. However, if you press a metal die into the wood or plastic part, the stamp often brands the material, ensuring that your mark remains after the foil has worn away.

More Visible

Stamping leaves a shiny finish that’s visible instantly to everyone. Therefore, the foil will offer a luxurious appearance and can grab the consumer’s attention. This is a huge advantage, especially in retail stores. People can spot the items easily, even when they’re next to the competitor’s version.

Promotes Brand Awareness

Foil-decorated packages often use metallic shades, so they feature a more upscale feel. Consumers see the products with gold-embossed text and perceive them as being something of higher value. Since people usually associate better quality with high price tags, they’ll see yours as worth considering or buying.

Visual cues like this will help you build your brand. Today’s marketplace is oversaturated with products, so your company’s image is crucial to set yourself apart from the competition. If others perceive you as offering high-value items, you’ll gain a strong reputation in the industry and generate more interest in your business.

Considerations and Limitations of Embossing Machines

Embossing machines do have one significant limitation: They cannot print small letters with real definition. However, if you can create the design to fit on the product, there shouldn’t be a problem. If you do require tiny characters, screen or pad printing might be more suitable.

Another consideration is the material choice for the die pressing into the stamping foil. Metals are often used and include steel, magnesium, copper, and brass.

Traditionally, magnesium is the least expensive, though it isn’t as durable. Brass and copper are preferable, though hardened steel is virtually indestructible and offers the best transfers.

Stamping products with surfaces that aren’t flat or have complex shapes can also be challenging. However, there are ways around it, such as being more careful when choosing the text and holding the item in place while the embossing machine does the job.

Stamping is an effective way to customize products and parts, but it’s difficult and expensive to achieve manually. Therefore, an embosser machine is the best solution because it makes the process simple and versatile.

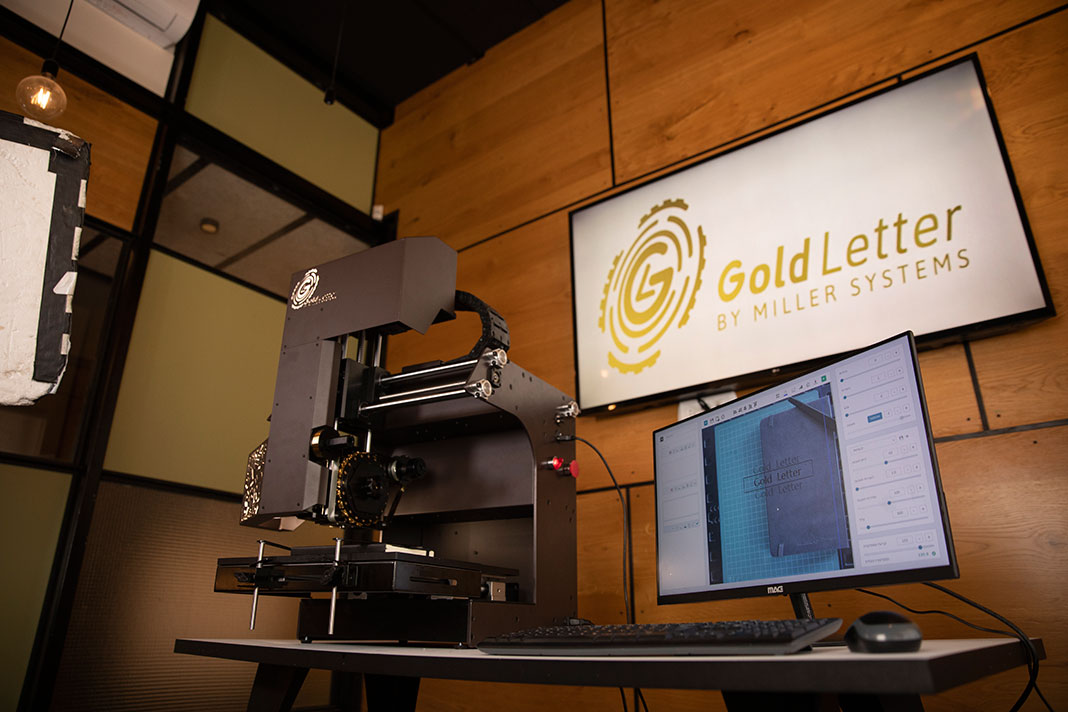

If you’re looking to stamp things for your next project, you’ve found the ideal solution. Gold Letter has expanded the boundaries of what people can do to upgrade their items and promote their brands.

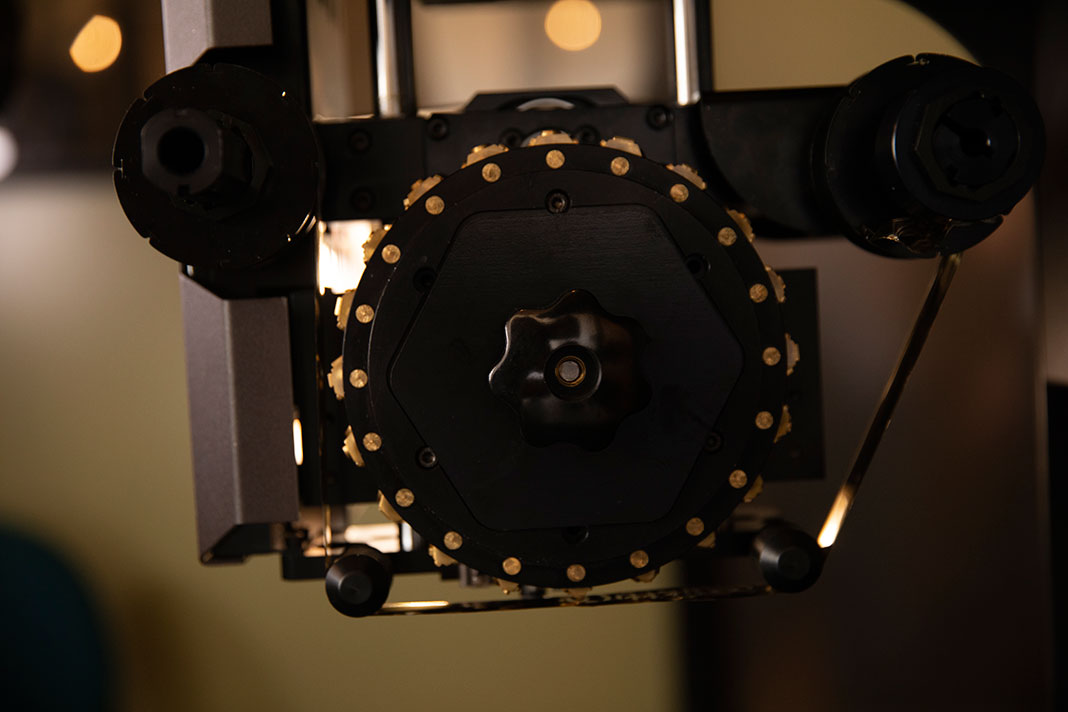

The Gold Letter hot foil stamping machine allows you to computerize and automate the process. Make countless customizations daily without requiring any special skills.

With the Gold Letter embossing machine, you have a camera that offers real-time images and a full preview of how things will look. Plus, there’s a wider stamping area so that you can print with ease. Check out the stamping machine that’s revolutionized the industry today.